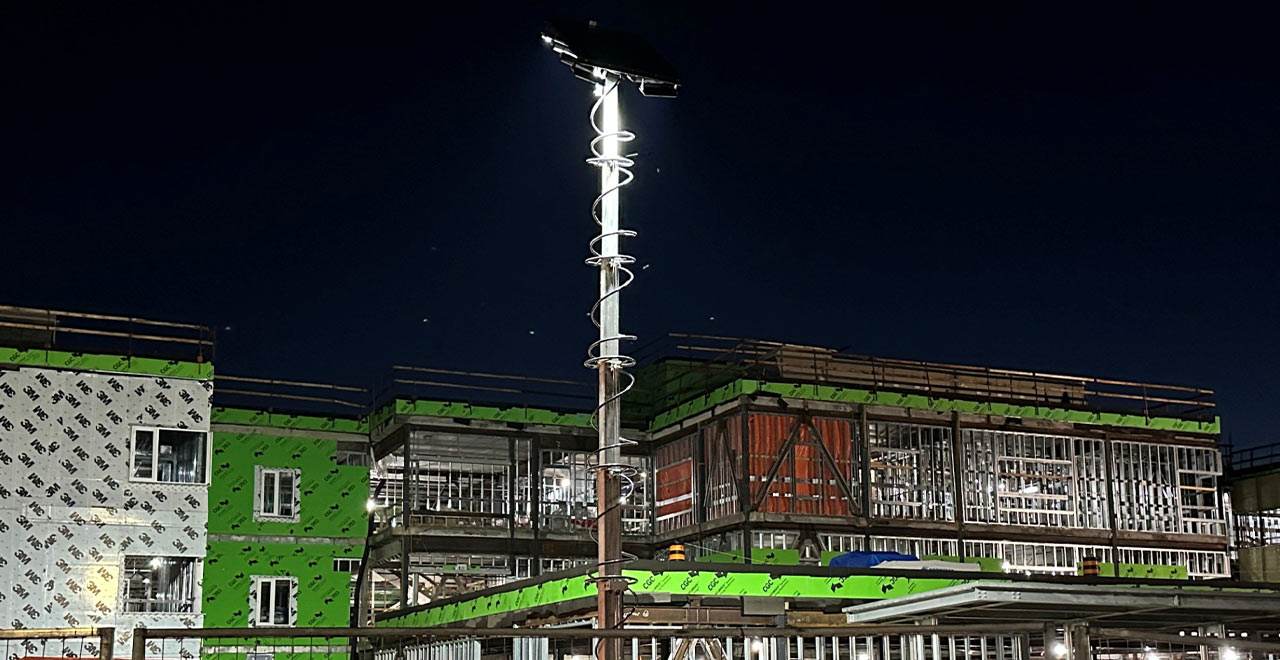

As temperatures drop, concrete contractors face a unique set of challenges. Cold weather can significantly slow the curing process, increase the risk of cracking, and leave finished surfaces vulnerable to damage. At the same time, fall rain and humidity can introduce excess moisture into building envelopes—complicating curing schedules and increasing the risk of costly delays.

For general contractors and concrete specialists alike, maintaining the right temperature and humidity balance is essential for quality results. REIC Specialty delivers temporary heating and dehumidification solutions that help keep projects on track, even when the weather doesn’t cooperate.

Why Moisture and Temperature Control Matter for Concrete Work

Concrete work is especially sensitive to temperature and humidity swings. In colder climates, the heat generated by hydration isn’t enough to keep concrete at ideal curing temperatures—especially during overnight lows. Meanwhile, excessive moisture can slow drying and compromise surface finishes. Left unchecked, these factors can cause:

- Curing Delays: Low temperatures extend curing times, impacting schedules and downstream trades.

- Strength Reduction: Inadequate curing temperatures reduce compressive strength, affecting structural integrity.

- Surface Defects: Freezing before proper setting leads to cracking, scaling, and poor finishes.

- Material Damage: Moisture trapped in forms, slabs, or adjacent materials can lead to warping, mold, or adhesion failures.

- Safety & Productivity Issues: Cold, damp sites create slip hazards and reduce worker comfort.

For projects operating on tight timelines, even minor delays caused by weather can cascade into costly overruns. Proactive temperature and moisture control is not just a best practice—it’s a necessity.

Typical Cold-Weather and Moisture Challenges for Contractors

Fall and early winter bring an unpredictable mix of cold air, high humidity, and rainfall. This combination can disrupt the curing of concrete and hinder construction momentum. Common challenges include:

- Rain Intrusion: Partially enclosed structures and fresh pours are especially vulnerable to water penetration.

- Humidity Buildup: Seasonal weather changes can trap moisture inside building envelopes, slowing the drying process.

- Cold Temperatures: Concrete and coatings require controlled curing environments to meet performance specifications.

- HVAC Gaps: Permanent climate systems are rarely operational during early or mid-construction phases.

Without an intentional climate control strategy, these conditions can delay schedules, compromise quality, and increase labor costs.

REIC Heating & Dehumidification Solutions for Cold-Weather Concrete

At REIC Specialty, we recognize that every construction site has distinct requirements. That’s why we offer a comprehensive range of temporary climate control solutions designed specifically for construction environments—including heating systems and dehumidifiers that work together to create stable conditions for concrete curing and other critical activities.

Desiccant Dehumidifiers

- Best For: Large-scale drying in cold, humid conditions

- Advantages: Performs exceptionally well in low temperatures; ideal for commercial buildings, warehouses, and multi-family projects. Desiccant systems remove moisture from the air, accelerating drying times and protecting materials even in fall and winter conditions.

Refrigerant Dehumidifiers

- Best For: Moderate drying in finished or occupied spaces

- Advantages: Portable and energy-efficient; well-suited for interior spaces nearing completion or build-outs where finishing work is underway.

Industrial Heating Options

We provide direct-fired, indirect-fired, and flameless heaters in various capacities to meet specific jobsite needs:

- Worker Comfort: Keeps crews warm and productive in cold weather.

- Curing Acceleration: Maintains optimal slab temperatures for proper hydration.

- Freeze Protection: Prevents damage to concrete, coatings, and water-sensitive materials.

Integrated Systems

The most effective strategy combines heating and dehumidification. Heating alone can worsen condensation problems, but when paired with dehumidifiers, it optimizes both temperature and humidity levels for maximum efficiency.

Best Practices for Concrete Contractors

To maximize performance and minimize delays during fall and winter, concrete contractors should follow these proven strategies:

- Plan Ahead

Incorporate temporary climate control into your preconstruction planning. Budget for heaters and dehumidifiers to avoid scrambling when temperatures drop. - Act Quickly After Rain

Rapid deployment of drying and heating equipment prevents moisture from saturating concrete, subfloors, or building envelopes. - Balance Temperature and Humidity

Heating without dehumidification often leads to condensation, which can undermine the curing process. A balanced approach ensures both heat and moisture are properly managed. - Monitor Conditions

Utilize moisture meters and sensors to monitor curing conditions in real time. Adjust equipment as needed to maintain target parameters. - Partner with Specialists

Work with a trusted provider like REIC Specialty to design a tailored solution that addresses the specific climate challenges of your project.

Scenario: Protecting a Commercial Concrete Pour

Imagine a mid-rise commercial project breaking ground in September. By October, framing and formwork are in place, and crews are preparing for interior slabs and drywall installation. Then, a week of heavy rain hits. Moisture saturates the structure, and nighttime temperatures dip into the 30s.

The Challenges:

- Trapped moisture in concrete and framing threatens to delay finishes.

- Cold, damp conditions make the site uncomfortable and unsafe.

- Applying coatings or finishing work now risks adhesion failures and mold.

The REIC Solution:

Our team would deploy a custom temporary climate control package, including:

- Desiccant dehumidifiers to stabilize humidity and dry materials efficiently.

- Indirect-fired heaters to raise interior temperatures without introducing additional moisture.

- Air movers and circulation fans are used to ensure even drying throughout the building.

Within days, the structure would be stabilized, allowing drywall and finishing work to proceed on schedule—without compromising quality or safety.

Why Contractors Choose REIC Specialty

Concrete contractors and general contractors across North America rely on REIC Specialty because we provide more than equipment—we provide partnership and expertise.

- Turnkey Service: From site assessment to equipment removal, we handle it all.

- Proven Track Record: Our brands, including Total Construction Rentals, Industrial Drying Solutions, and Cahill Heating, have decades of experience.

- Rapid Response: With 19 locations across North America and 24/7 emergency availability, we’re there when weather threatens your schedule.

- Tailored Solutions: We scale our solutions to fit projects of any size, from small build-outs to large industrial sites.

- Safety & Compliance: All our equipment meets strict industry standards, ensuring reliable and safe operation.

Be Ready Before the Cold Hits

Cold weather and moisture challenges don’t have to derail your concrete schedule. By partnering with REIC Specialty, you can proactively protect your work, keep crews productive, and maintain your timeline—even in unpredictable fall and winter conditions.

Whether you’re facing a sudden cold snap or planning for seasonal change, REIC’s heating and dehumidification solutions give you the control you need to keep curing on schedule and quality high.

Contact REIC Specialty today to schedule a project consultation or develop an emergency response plan. With our expertise, equipment, and 24/7 support, your next cold-weather concrete project can stay safe, dry, and on track.